Our Discovery Philosophy

At FloStor, we believe that great solutions begin with a thorough understanding of your challenges. Our discovery process is designed to uncover your specific needs, constraints, and goals.

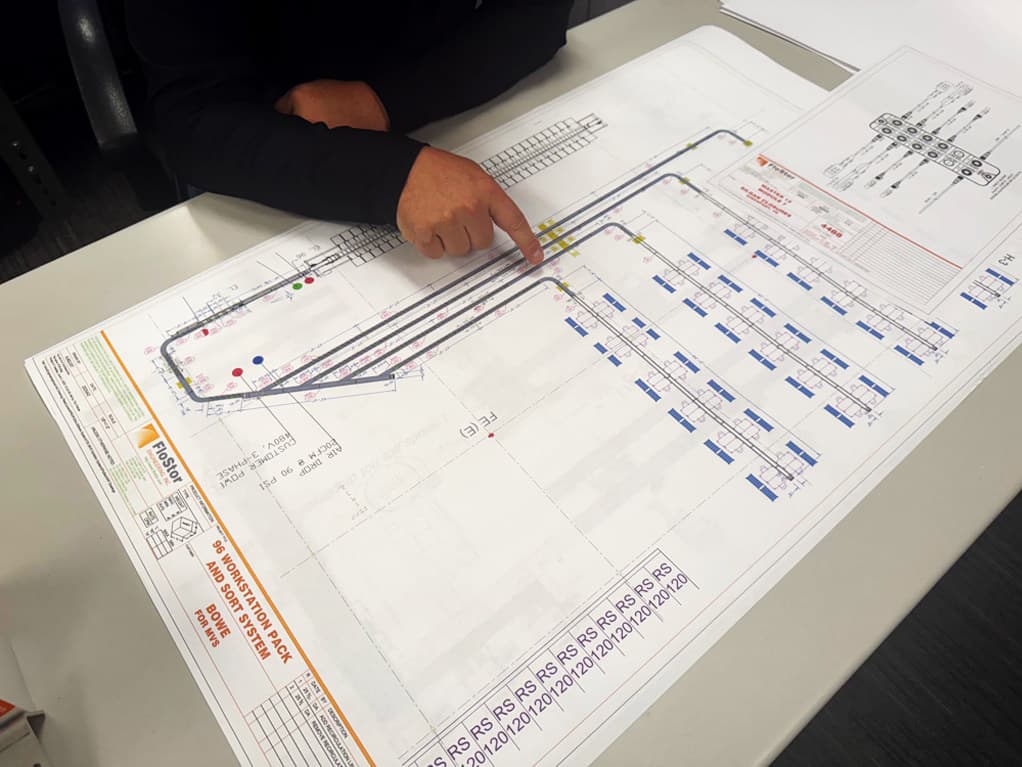

FloStor Systems Sales Engineers review your current processes in light of productivity goals, forecast demand, product development, and capital budget. This collaborative evaluation generates the concept and design criteria for incremental system improvements or a comprehensive new system.

"We try to go to customers and ask them what their needs are, and what their expectations are. And by doing this, we get a feeling for what they're looking for."

— Bob Weeks, Founder of FloStor, Inc.

Building Partnerships Through Discovery

FloStor begins by zeroing in on your company's challenges, requirements, and business objectives. Our Systems Sales engineers work closely with your engineering staff to learn about your current processes, and then compare them to your productivity goals, demand forecasts, product development and capital budget.

"We try to develop relationships with our customers. I think that's very important, because if you can develop that kind of relationship, it's a lot more fun doing a job. You can do it better."

— Bob Weeks, FloStor Founder

This collaborative evaluation is designed to generate the concept and design criteria for your own unique solution, whether it involves incremental system improvements or a comprehensive new system.

Our Discovery Methodology

Our structured discovery approach ensures we thoroughly understand your operation before proposing solutions. Each step is carefully designed to gather critical insights about your business.

Initial Consultation

We start with a comprehensive discussion to understand your business objectives, difficulties, and operational requirements.

- Business objectives: What are your overarching goals and strategic priorities?

- Difficulties: What specific challenges are you currently facing?

- Operational requirements: What are the essential needs and constraints of your operations?

"A customer can come to us, and they have a goal of producing a specific product, of handling a certain number of product. Working together, we can take a blank sheet of paper, and turn it into a layout, a concept, and how to go about improving their business."

— Chuck Ireland, FloStor Vice President

Site Assessment

Our team conducts a detailed, on-site evaluation of your facility that goes beyond a simple walkthrough.

- Physical Space Measurement: Precise measurements to identify spatial constraints and opportunities

- Existing System Analysis: Review of current equipment, storage systems, and workflow layouts

- Infrastructure Evaluation: Assessment of structural integrity, power supply, and environmental conditions

- Traffic Flow Observation: Analysis of personnel and material movement patterns

- Future Expansion Considerations: Evaluation of scalability requirements

Workflow Analysis

We analyze your current processes to identify bottlenecks, inefficiencies, and opportunities for automation and optimization.

- Material Handling: Assessing movement of goods to optimize storage, retrieval, and transport

- Order Fulfillment: Evaluating speed and accuracy of processing, picking, packing, and shipping

- Production Processes: Analyzing manufacturing or assembly lines to identify bottlenecks

- Inventory Management: Reviewing storage strategies and replenishment processes

- Information Flow: Examining data flow across departments and systems

"What I find most beneficial about working with FloStor is the relationship. By understanding what we need to do and what we need to accomplish, the collaborative effort is that much smoother."

— Duke Golden, Director of Manufacturing, IGT

Data Collection

We gather relevant data on throughput, peak volumes, seasonal variations, and other metrics to inform our solution design.

- Create Data-Driven Solutions: Ensure recommendations based on factual evidence

- Optimize System Capacity: Design systems that can handle current and future demand

- Improve Forecasting Accuracy: Accurately predict future needs

- Measure System Performance: Track key metrics to evaluate effectiveness

- Validate ROI Projections: Provide accurate financial projections

- Minimize Risk: Identify potential problems and develop contingency plans

Discovery Deliverables

Our discovery phase concludes with a comprehensive report that provides the foundation for our solution development process.

- Summary of findings and observations

- Identified challenges and opportunities

- Preliminary solution concepts

- Initial ROI projections

- Recommended next steps

"The most beneficial thing of working with FloStor is the people. The project management has been nothing short of outstanding. The people that we've worked with have been very patient, very diligent and accurate in the plans they produced at the beginning, and their estimations of capacity have been spot on."

— Saul R. Smith, Agron, Inc.

A Partnership Approach

Our discovery process lays the groundwork for a successful long-term partnership. We believe in building relationships that extend beyond a typical vendor-client dynamic.

"It's more of a partnership than a customer-supplier relationship, because of the collaboration and the fact that they understand our business."

— Mr. Golden, IGT

Ready to Begin Your Discovery Journey?

Contact our team to schedule an initial consultation and take the first step toward optimizing your material handling operations.

Start Your Discovery Process