The food and beverage industry faces unique challenges including strict sanitation requirements, temperature control needs, allergen management, and regulatory compliance. Meeting these demands while maintaining efficiency requires specialized material handling solutions designed specifically for food processing environments.

Our food and beverage industry solutions integrate specialized equipment, automation technologies, and workflow design to create systems that ensure product integrity, safety, and traceability while maximizing throughput and minimizing waste. From ingredient handling to finished product distribution, we provide comprehensive material handling systems that address your industry-specific requirements.

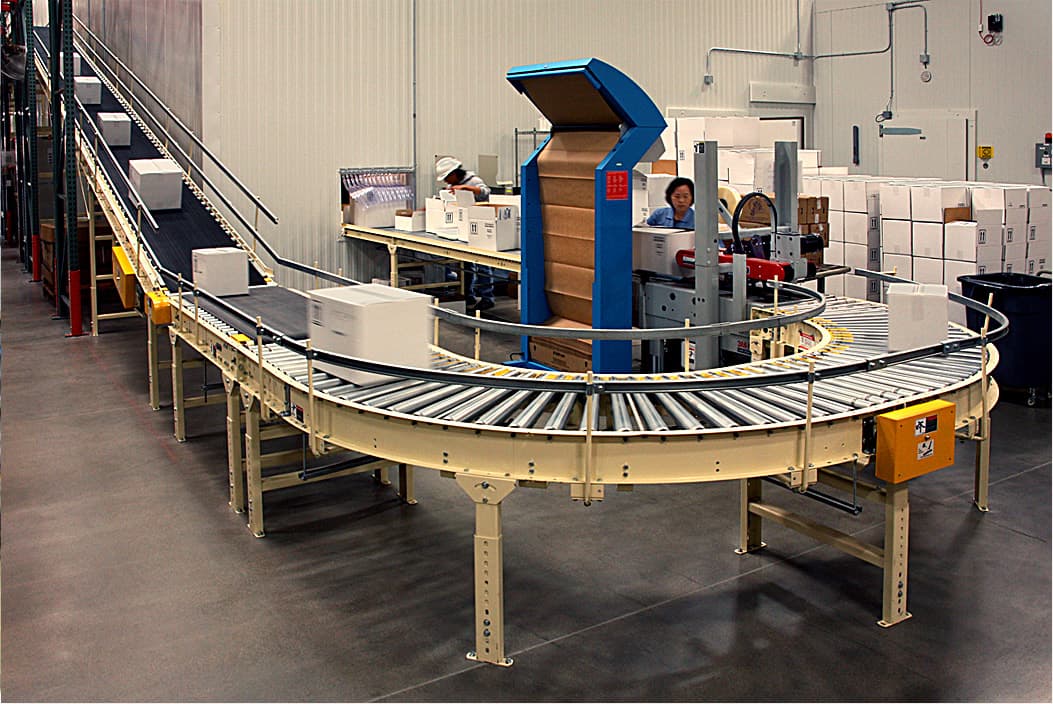

Specialized conveyor solutions designed for food safety with washdown capabilities, sanitary materials, and open designs for easy cleaning and inspection.

Temperature-controlled material handling systems designed to maintain product integrity throughout processing, storage, and distribution operations.

Vision-based and weight-based systems for product sorting, inspection, and quality control that ensure product consistency and safety.

Integrated cleaning solutions that enable efficient sanitation of processing equipment with minimal disassembly and downtime.

End-to-end tracking systems that provide complete product visibility from ingredients through production to final distribution.

Integrated systems for primary packaging, case packing, palletizing, and stretch wrapping that maintain quality and efficiency.

Reduce contamination risks with equipment designed specifically for food processing environments

Meet FDA, USDA, and FSMA requirements with purpose-built systems and documentation

Minimize cleaning and changeover time with quick-clean designs and efficient sanitation systems

Reduce labor, water, and energy usage through efficient process design and automation

Maintain consistent product quality through gentle handling and integrated quality controls

Adapt quickly to product changes and seasonal demand with configurable systems

Our solutions are tailored to address the unique challenges of diverse food and beverage production environments.

Specialized solutions for milk, cheese, and yogurt processing with strict temperature controls

Efficient handling systems for fragile products with high changeover requirements

Washdown-ready systems designed for strict hygiene and temperature control requirements

High-speed handling solutions for bottles, cans, and packaging with integrated quality control

Cold environment solutions for frozen product processing, packaging, and storage

Gentle handling systems that minimize damage while ensuring efficient throughput

Flexible systems for multi-ingredient assembly with integrated quality verification

Custom handling solutions for unique products with specific processing requirements

We evaluate your specific requirements, production environment, and regulatory needs to identify the optimal solution approach.

Our engineers develop custom handling solutions that address your specific food safety, quality, and efficiency requirements.

We apply sanitary design principles to ensure all equipment meets food safety standards and cleaning requirements.

Our specialized teams install, integrate, and commission your systems with minimal disruption to existing operations.

We provide comprehensive testing, documentation, training, and ongoing support to ensure operational success.

Reduction in cleaning time

Increase in production throughput

Food safety compliance rate

Reduction in product waste

* Based on typical client implementations in food & beverage processing environments

Contact our food industry specialists to discuss how our material handling solutions can improve your safety, compliance, and operational efficiency.