In today's competitive business environment, effective space utilization directly impacts operational efficiency and profitability. Modern storage systems transform your facility into a strategic asset that optimizes cubic space utilization, improves inventory access, and enhances workflow productivity.

Our comprehensive approach integrates structural engineering expertise with operational workflow analysis to create storage solutions that maximize capacity while ensuring safety, accessibility, and adaptability to your evolving inventory requirements.

The most versatile and widely-used racking system, providing direct access to every pallet position while optimizing both accessibility and storage density.

Storage configuration that places two pallet positions back-to-back, increasing density while maintaining good selectivity for operations with limited SKU counts.

High-density storage system that eliminates multiple access aisles, allowing forklifts to drive directly into the rack structure to store and retrieve pallets.

Dynamic storage system using inclined nested carts that automatically push back when a new pallet is loaded, maximizing density while maintaining good selectivity.

Dynamic high-density system using inclined roller tracks to allow pallets to flow from loading to unloading side, ideal for FIFO inventory management.

Specialized storage system with horizontal arms extending from vertical columns, designed for storing long, bulky items like lumber, piping, or furniture.

Dynamic shelving system designed for carton and case picking operations, utilizing inclined roller tracks or wheels for automatic front-facing product presentation.

Versatile storage solution for hand-loaded items and small parts, available in open or closed styles with adjustable shelf levels for maximum flexibility.

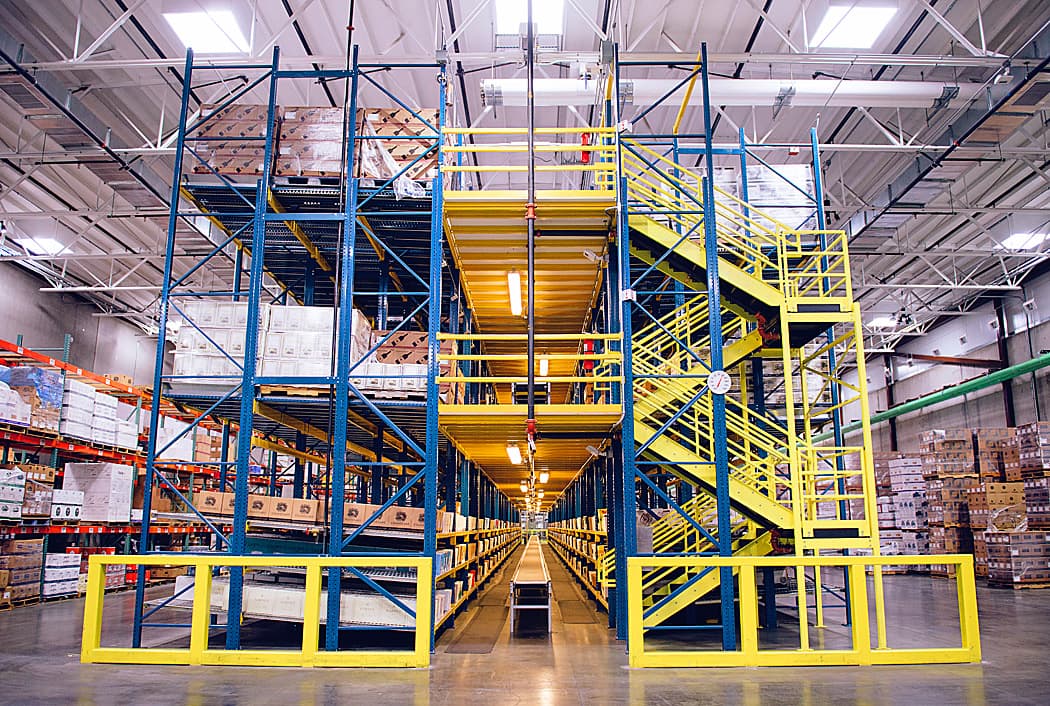

Structural platforms that create additional levels of storage or work areas within your existing facility, effectively doubling or tripling usable floor space.

Maximize cubic storage capacity with vertical configurations that minimize aisle requirements

Strategic product placement and optimized picking paths that reduce travel time and increase efficiency

Properly designed storage systems that minimize product damage and reduce workplace injuries

Organization systems that support proper FIFO/LIFO protocols and accurate inventory management

Modular systems that can be reconfigured or expanded as your business requirements evolve

Customizable configurations that adapt to changing SKU profiles and seasonal inventory variations

Our storage solutions serve diverse industry requirements with customized systems designed for specific operational challenges.

High-velocity picking systems with both bulk storage and case-level access

Raw material, WIP, and finished goods storage with line-side integration

Temperature-controlled storage with FIFO rotation for perishable inventory

Parts storage systems with rapid access for service and assembly operations

Back-of-house storage and customer-facing merchandising systems

High-security storage with tracking systems for regulatory compliance

Temperature-sensitive storage maximizing space in costly refrigerated environments

High-density shelving for archival documents with controlled access capabilities

We analyze your inventory profiles, throughput requirements, and growth projections to identify optimal storage solutions.

Our engineers develop customized storage configurations that balance capacity, accessibility, and operational workflow.

We perform load calculations, seismic analysis, and safety reviews to ensure system integrity and regulatory compliance.

Expert installation teams efficiently construct your storage systems with minimal disruption to ongoing operations.

We complete thorough safety inspections and provide certification documentation to ensure your storage system meets all regulatory requirements.

Increase in storage capacity

Reduction in picking time

Improvement in inventory accuracy

Less time spent locating products

* Based on typical client implementations in pallet rack storage environments

Contact our storage system specialists to discuss how custom racking and shelving solutions can maximize your facility's efficiency and storage capacity.