In today's complex manufacturing and distribution environments, making the right operational decisions is critical to success. Simulation software provides a powerful virtual platform to test concepts, validate designs, and optimize processes without the risks and costs associated with physical implementation.

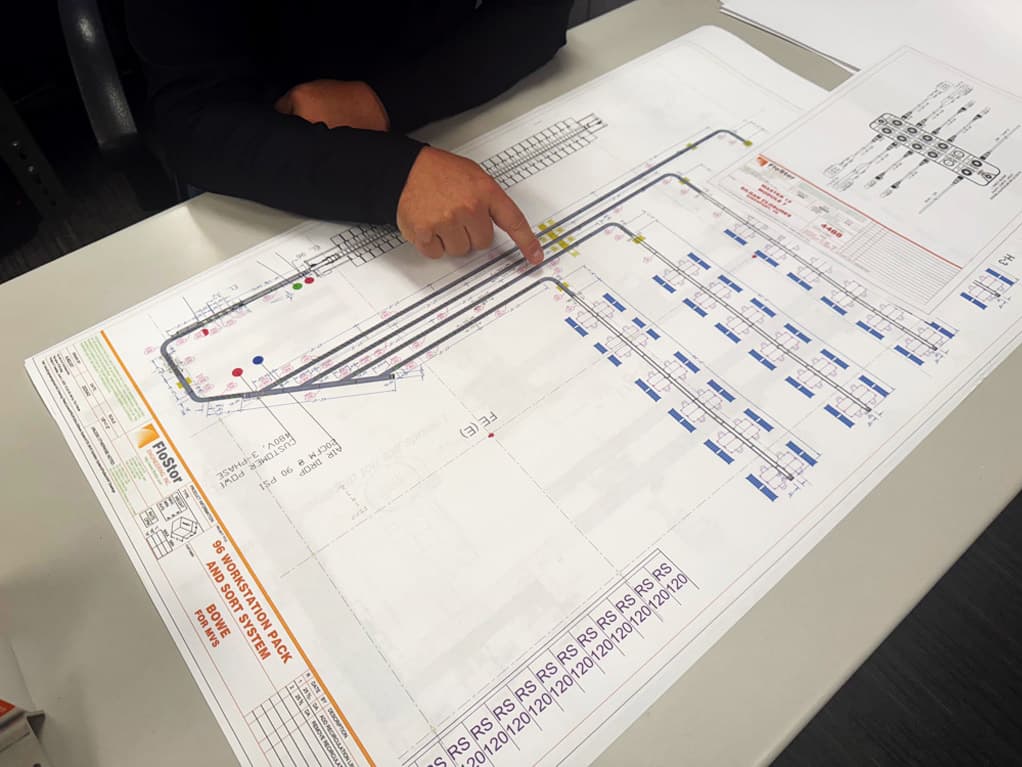

Our simulation solutions allow you to create detailed digital models of your facility, equipment, and processes to identify bottlenecks, test various scenarios, and visualize outcomes before committing resources. Whether you're designing a new facility, reconfiguring an existing operation, or implementing automation, simulation provides the insights needed to make confident decisions.

3D modeling and simulation tools that optimize space utilization and material flow by testing various facility layouts and configurations.

Dynamic modeling tools that analyze and optimize manufacturing and distribution processes to identify inefficiencies and validate improvements.

Specialized tools that analyze and visualize the movement of materials through your facility to identify congestion points and optimize flow patterns.

Advanced simulation tools that model robotic systems and automated equipment to validate performance, identify collisions, and optimize control logic.

Create virtual replicas of your physical operations that continuously update with real-time data to enable ongoing optimization and predictive analytics.

Data-driven software solutions that analyze production data to identify trends, predict issues, and provide actionable insights for continuous improvement.

Accelerate project timelines by validating designs and processes before physical implementation

Identify and address potential issues in the virtual environment to avoid costly physical modifications

Test multiple scenarios to identify the optimal configuration for maximum throughput and efficiency

Validate operational changes in a risk-free virtual environment before real-world implementation

Make data-driven decisions based on quantifiable metrics and visual representations of potential outcomes

Model future growth scenarios to ensure current implementations can scale to meet evolving business needs

Our simulation and software solutions provide value across diverse operational challenges and improvement initiatives.

Optimize new facility layouts or expansion projects to maximize space utilization and flow efficiency

Identify and eliminate bottlenecks in existing operations to increase throughput and reduce costs

Validate and optimize automated systems before installation to ensure expected performance gains

Model future demand scenarios to ensure operations can scale to meet changing business requirements

We gather operational data, facility dimensions, process flows, and performance metrics to create an accurate simulation foundation.

Our engineers build detailed digital models of your facilities, processes, and systems using specialized simulation software.

We test multiple scenarios and configurations to identify optimal solutions and validate performance improvements.

Our team analyzes simulation results to identify bottlenecks, inefficiencies, and opportunities for optimization.

We provide detailed recommendations and support the implementation of optimized solutions in your actual operation.

Average throughput increase

Space utilization improvement

Reduction in project implementation risks

Typically 6-12 months for standard implementations

* Based on typical client outcomes in simulation and digital twin projects

Contact our simulation specialists to discuss how virtual modeling can optimize your facility design and operational processes.